coal2thorium.com  Converting Power Plants

From

coal2nuclear

Converting Power Plants

From

coal2nuclear

Chapter 1

THE THORIUM-FUELED

NUCLEAR BOILER

Directory

The purpose of this page is to introduce you

to our best "Technology Opportunity."

Thorium-fueled liquid

reactors

The

best "Technology Opportunity" for both Global Warming and rising

electricity costs.

A Thorium-Fueled Liquid Reactor as

described by Dr. Edward Teller, inventor of the hydrogen bomb.

This web site will focus on the "Heavy" electricity

industry 1,000 megaWatt (e) thorium-fueled liquid reactor designed by EBASCO

(1972) but never built.

Cruder than a Civil-War locomotive boiler, a liquid reactor heated

boiler should cost less to build than its equivalent coal heated boiler.

A QUICK INTRODUCTION TO MOLTEN SALT REACTORS

MAGIC TEAM: THORIUM-FUELED MOLTEN SALT REACTORS

About using molten

salt as a coolant.

QUICK HISTORY OF

THORIUM-FUELED MOLTEN SALT REACTORS

Nuclear Aircraft Engines 1946-1962

After

Nuclear Aircraft Engines

Dr. Ralph Moir and Dr.

Edward Teller (inventor of the Hydrogen Bomb) advocate MSRs

THE GOOD:

Molten Salt Reactor advantages

THE BAD: Molten Salt Reactor shortcomings

THE UGLY: When running,

thorium's U-232 radiation keeps terrorist's hands out of the cookie

jar.

THE ROUGH SPOTS:

General Considerations

Uncertainties, unanswered questions

References

Molten Salt

Reactor Basics

More about Molten

Salt Reactors

Advanced LIQUID FLUORIDE

THORIUM (LFTR) Nuclear Reactors

A molten salt reactor and your hot water heater are similar devices.

MSR - Safety and Licensing Aspects of the Molten Salt Reactor - 120507.pdf

________________________________________________________________________________________

Introduction:

We are talking about a

combination of TWO entities:

1. Thorium instead of Uranium as a

nuclear fuel.

2. Unpressurized (incapable of exploding) molten salt cooled liquid fuel reactors rather than

high pressure (capable of exploding) water cooled solid fuel rod reactors.

A QUICK INTRODUCTION TO MOLTEN SALT REACTORS

A QUICK INTRODUCTION TO MOLTEN SALT REACTORS

1.

Solid salt, if heated hot enough, will melt into a clear water-like liquid

(color-coded yellow in sketch at right). At the temperatures discussed here, the salt is far

below its boiling point and, since the salt has little vapor pressure, Molten

Salt reactors are unpressurized and thus incapable of making a steam-like

explosion.

2.

Uranium can be dissolved in molten salt.

A tub of molten salt with some radioactive uranium dissolved in it (think blood

- which carries nutrients) will become a

nuclear reactor if rods of synthetic non-flammable "nuclear" graphite (vertical black bars in reactor sketch) are

inserted into the liquid salt pool to promote nuclear fission (think muscle -

which turns nutrients into energy).

3.

If the pool becomes hotter than the design temperature, the liquid

salt expands, reducing the concentration of radioactivity near the nuclear graphite

rods, thereby reducing the intensity of the nuclear chain reaction. If the pool

becomes cooler, contraction of the liquid salt intensifies the chain reaction,

making the pool become hotter. A Molten Salt reactor will “load follow” (think

“cruse control”) over a surprisingly large portion of its power range.

Control rods can bring the reactor down to "idle". Total shut down

can be achieved in a few seconds by draining the fuel salt into the dump tanks.

4.

The first heat exchanger heats a second loop of clear non-radioactive

molten salt called "coolant salt" is used to safely carry the reactor's heat to

the outside world. Coolant salt then heats the second heat exchanger to

make steam to drive an electricity generator.

5.

Some types of molten salt reactors need a

“pool cleaner” (the

gray "Chemical Processing" module) system to keep the uranium concentration proper

by adding fresh fuel while removing the nuclear waste. With some thorium

types, fresh make-up thorium is added as needed for up to thirty years at which

time the fuel salt has to have its dissolved waste products removed.

6. If,

for any reason, the reactor gets too hot,

a freeze plug in the reactor tank’s bottom melts, causing the fuel-carrying

molten

salt to

drain away from the nuclear graphite rods down into passively air cooled dump tanks (blue) located

beneath the reactor. There, away from the graphite rods, the chain reaction ceases

and, if left long enough, the molten salt will cool sufficiently to solidify.

Heaters will be needed to re-melt the salt.

________________________________________________________________________________________

MAGIC TEAM: THORIUM-FUELED MOLTEN SALT REACTORS

MAGIC TEAM: THORIUM-FUELED MOLTEN SALT REACTORS

(We are talking about the basic THORIUM CONVERTER reactor that makes its own radioactive

fuel and then consumes it.)

From

here on, things just get better.

Once started with a small amount of radioactive uranium or plutonium, Molten

Salt reactors will continue to run on non-radioactive thorium by first

converting the dissolved thorium into radioactive uranium-233 and then

fissioning (breaking) that atom. These two reactions will happen naturally

and simultaneously when you get things right.

Thorium is found

everywhere,

is 4 times as common as all forms of uranium combined, and, used this way in liquid form, produces 250 times as much

heat energy in a

single reactor pass as

a solid uranium fuel rod. This means thorium heat will cost less than 1/8,000th as much as coal

heat. This also means, since so little is needed, we'll never consume all the thorium available on

Planet Earth. Today, thorium is simply a waste tailing of rare earth

mining.

HOW NON-RADIOACTIVE

THORIUM WORKS

HERE IS HOW

NON-RADIOACTIVE 232-THORIUM CAN BECOME RADIOACTIVE 233-URANIUM (Breeding Reaction)

AND THEN MAKE HEAT (Chain Reaction)

(From the Moir-Teller article.)

The cost

of a molten salt reactor boiler should be in the same ball park as less than

twice a coal

burning boiler. Being unpressurized, the molten salt reactor can be

made out of relatively thin metal - Hastelloy-N for corrosion resistance - and

the unpressurized steam generators are also inexpensive-to-make thin metal

"shell and tube" devices. Nuclear graphite is a semi-synthetic

material that can be made from coal. The

particular salt used is not damaged by radiation so should last forever. 3

feet of concrete will contain the reactor's radiation and concrete is cheap - we

make roads out of it. The Chinese began a thorium molten salt reactor development program

in late 2010.

http://en.wikipedia.org/wiki/Nuclear_graphite

Like the

hot water heater in your basement, molten

salt reactors do not need operators. They "load follow" over most of

their power range much like the cruise control in your car. This is

because when the fuel salt gets hotter than the set temperature, it expands,

thinning out the amount of thorium-232/uranium-233 fuel that can get near the

reactor's graphite core. This, in turn, reduces the amount of heat the

fuel salt can make. If the thermal load on the reactor increases and the

fuel salt becomes cooler, the fuel salt contracts, allowing more fuel to get

near the reactor's graphite core, causing additional heat to be produced.

This process is quick, taking only 10 seconds or less (molten salt reactors had

to be powerful and fast to be candidates for powering large airplanes).

Control

rods are present to bring the reactor down to an "idle." If, for some

reason the reactor must be turned off completely, it will be necessary to go

through a month-long "fissile fuel cycle" using some enriched uranium,

plutonium, etc., to re-start the conversion reaction that converts

non-radioactive thorium-232 into the immediately consumed radioactive

uranium-233 that actually makes the heat.

The type

of Molten

Salt reactor being advocated here for repowering coal burning boilers can

run on thorium 30 years flat-out by adding more non-radioactive thorium once a year. It produces

about 1% the hazardous nuclear waste of an equivalent conventional reactor.

At the end of 30 years it needs to have the fuel-carrying salt

purified (the salt that

circulates through

the reactor and first heat exchanger) and the reactor's graphite rods replaced -

then it's good to go again for another 30 years.

There appears to be no practical obstacle to vastly different sizes of Molten

Salt reactors.

A more

detailed introduction by a professional writer in a hurry.

MSR - The Thorium Paradigm .pdf

A

conservative

introduction.

http://energyfromthorium.com/joomla/index.php?option=com_content&view=article&id=64&Itemid=63

An

on-line Wikipedia article:

http://en.wikipedia.org/wiki/Molten_salt_reactor

http://en.wikipedia.org/wiki/Thorium_fuel_cycle

________________________________________________________________________________________

QUICK HISTORY OF

THORIUM-FUELED MOLTEN SALT REACTORS

QUICK HISTORY OF

THORIUM-FUELED MOLTEN SALT REACTORS

Born in

Cold-War secrecy, this reactor type was first developed as a nuclear aircraft engine

in the 1950s by Pratt and Whitney, test-stand run successfully, given multiple rides

in a B-36 bomber to get crew shielding right, and then abandoned by the U.S. military over the next decade

when thorium proved to have no military weapons value.

A ten

megaWatt Molten Salt Reactor was later built at Oak Ridge National

Laboratories. It ran well for about 5 years on both pure and various blends of

thorium, uranium, and plutonium.

and various blends of

thorium, uranium, and plutonium.

Solid

thorium fuel rods were used experimentally in the 1957 conventional 60 MWe "Shippingport"

reactor near Pittsburgh, PA, between 1977 and 1982.

http://en.wikipedia.org/wiki/Shippingport_Reactor (Right, Shippingport

reactor vessel.)

A 1,000

megaWatt (e) Molten Salt electricity generating unit was designed by EBASCO (a

consortium of 15 Midwest power companies) for Oak Ridge National Laboratories in

1965, and then shelved in favor of established conventional solid fuel

reactors.

The MSR

program had near-zero weapons value and was cancelled about 1974 when the government decided in favor of

funding liquid metal fast breeder reactors which could make far more weapons

material faster.

The liquid

metal fast breeder reactor program, in turn, was killed for nuclear proliferation

reasons in 1994 by an administration with strong anti-nuclear ties.

Czech Republic, France, China (molten salt reactor development,

large thorium deposits, small uranium deposits), India (solid thorium fuel rod

reactors, large thorium deposits), are

currently active in thorium energy research with Norway (large thorium

deposits), Japan, and Russia

looking on.

________________________________________________________________________________________

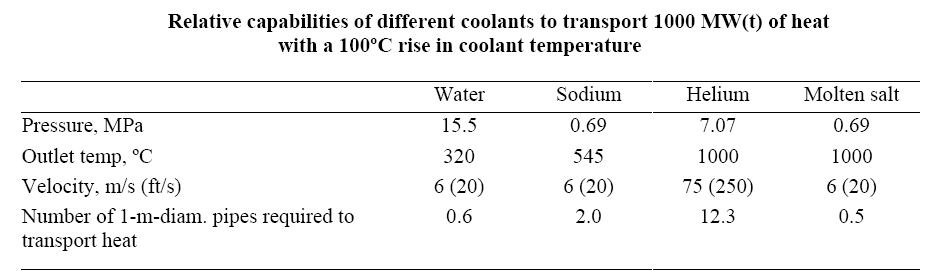

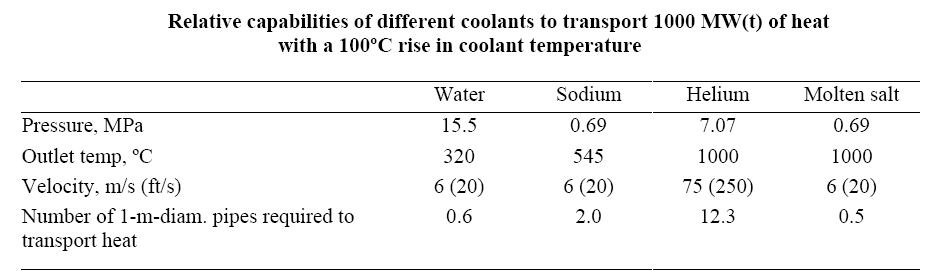

About using molten

salt as a coolant.

About using molten salt as a

coolant.

________________________________________________________________________________________

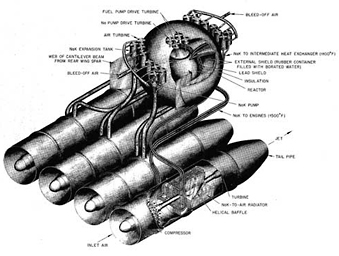

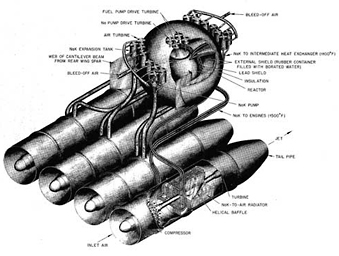

Nuclear Aircraft Engines 1946-1962

Nuclear Aircraft Engines 1946-1962

"Aircraft Nuclear Propulsion (ANP) Program",

Mid-1950s

Molten Salt Reactors (MSRs) - a type of Nuclear

Reactor

The most interesting application of molten salt

technology was the development of the Molten Salt (Nuclear) Reactor

(MSR). Originally developed to power a deep penetration bomber for

targets in the Soviet Union during the early Cold War (1946 - 1962),

it is a remarkable, yet virtually unknown reactor. Part of the problem

was the limited geographical experience of the MSR as both operating

MSRs were built only at Oak Ridge National Laboratory (ORNL), near

Knoxville, Tennessee, USA.

The first MSR was the 1954, 100-hour operation of the

Aircraft Reactor Experiment (ARE) at ORNL. Its sole purpose was to

demonstrate the then unheard of notion of operating a reactor at red

heat (~750°C; ~1,550° F) with a molten fuel and coolant consisting of

melted fluoride salts (sodium fluoride, NaF; zirconium fluoride, ZrF 4;

and UF4 [enriched in 235U]).

The second MSR was a

civilian power plant prototype, the Molten Salt Reactor Experiment

(MSRE)7.

Hugely successful, it was ignored by the US Atomic Energy Commission (US

AEC), which had decided to favor the Liquid Metal Fast Breeder Reactor (LMFBR).

The Director of ORNL, Dr.

Alvin Weinberg, pushed for the MSR, but was fired for his efforts.

The notable features of this reactor are:

● Meltdown proof

● Does not produce weapons grade plutonium

● Has inherent non-proliferation features

● Thousands of years of energy

● Simplified fuel cycle (no fuel elements nor reprocessing required)

● Its wastes are simpler and less toxic than current nuclear wastes

● Only hundreds of years of storage versus thousands for the current

wastes

● Can completely destroy military plutonium

● Can burn the existing wastes (spent fuel)!

● Higher thermal efficiencies (operates at a "Red Heat"; ~700° C [1,260°

F])

The above was written and created by

Bruce Hoglund

<bhoglund@earthlink.net.DoNotSpamMe>, © 1997

Please send me any HELPFUL comments. Responsible use is allowed as long as the

author is cited.

Above from:

MSR -

What is Molten Salt & Its Technology_ .pdf

(Right) In fact, there were

TWO nuclear aircraft engines under development at the time. Heat Transfer

Reactor Experiment - 3 (HTRE-3) is the large one above and on the left in

the small picture. It came from Pratt & Whitney. The other one,

HTRE-1

(later rebuilt as HTRE-2) was an air-direct-core-cooled General Electric design.

(Small image above from Wikipedia (click

on it for large image), large

image (above) taken by author Sept, 2010 from Idaho National Labs parking lot.)

"The US Aircraft Reactor

Experiment (ARE) was a 2.5 MW

thermal

nuclear reactor experiment designed to attain a high

power density for use

as an engine in a nuclear powered bomber. It used the molten fluoride salt

NaF-ZrF4-UF4

(53-41-6 mol%) as

fuel,

was

moderated by

beryllium oxide (BeO), used liquid

sodium as a secondary

coolant and had a peak

temperature of 860 °C. It operated for a 1000-hour cycle in 1954. It was the

first molten salt

reactor. Work on this project in the US stopped after

ICBMs made it obsolete. The designs for its engines can currently be viewed

at the

EBR-I memorial building at the

Idaho National

Laboratory." - -

http://en.wikipedia.org/wiki/Aircraft_Nuclear_Propulsion

For more information about the

airplane photos, see ASME web article:

http://www.asme.org/kb/news---articles/articles/nuclear/molten-salt-reactors

________________________________________________________________________________________

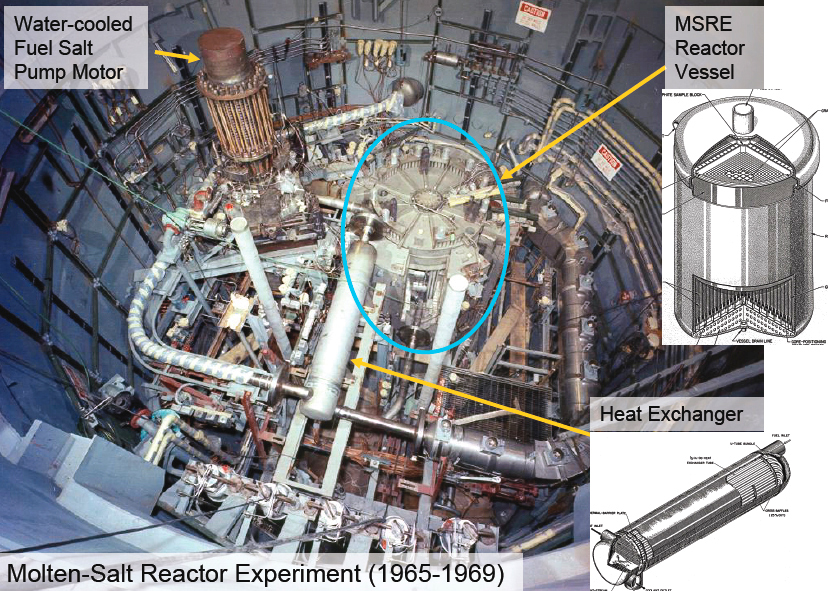

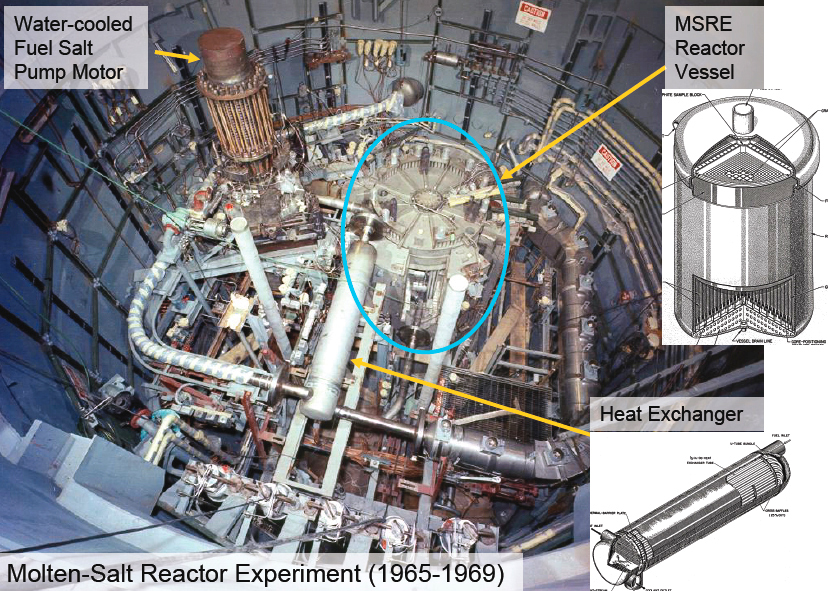

After

Nuclear Aircraft Engines

After

Nuclear Aircraft Engines

Molten-Salt

Reactor Experiment 1965 to 1969.

(Oak Ridge National Labs Photo from Kirk Sorensen's 2011 TEA talk slides.)

Notice the water-cooled pump motor. The 1,200°F reactor was so hot you

could take a photograph of it at night without a flash. Both the heat and

corrosiveness of the salt makes this a place to stay away from. EBASCO did

some unrecognized brilliant engineering and came up with a far better reactor

confinement cell design.

(Left) SHOW ME THE FIRE-HOT HEAT.

Molten salt-to-air heat exchanger running

full-blast. 1,200°F+ is the normal discharge temperature of this reactor.

It can replace most coal, natural gas, and oil fires. Molten salt reactor

experiment, Oak Ridge National

Laboratories.

Temperature Colors - 540.jpg

(Right) Assembling the graphite core of the

experimental 10

megaWatt Molten Salt Reactor (MSRE).

"The MSRE's piping, core vat and structural

components were made from

Hastelloy-N and its

moderator was a

pyrolytic graphite core. The fuel for the MSRE was

LiF-BeF2-ZrF4-UF4

(65-30-5-0.1), the graphite core

moderated it, and its secondary

coolant was

FLiBe (2LiF-BeF2),

it operated as hot as 650 °C (1,200°F) and operated for the equivalent

of about 1.5 years of full power operation."

From:

http://en.wikipedia.org/wiki/Molten-Salt_Reactor_Experiment

________________________________________________________________________________________

Dr. Ralph Moir and Dr.

Edward Teller (inventor of the Hydrogen Bomb) advocate MSRs

From leading nuclear experts:

Dr. Ralph Moir and Dr.

Edward Teller (inventor of the Hydrogen Bomb) advocate MSRs

MSR - Thorium-Fueled Underground Power Plant Based On Molten Salt

Technology - moir teller .pdf

(P-334, NUCLEAR TECHNOLOGY, VOL. 151, SEP. 2005)

This paper addresses the problems posed by running out of oil

and gas supplies and the environmental problems that are due to greenhouse gases

by suggesting the use of the energy available in the resource thorium, which is

much more plentiful than the conventional nuclear fuel uranium. We

propose the burning of this thorium dissolved as a fluoride in molten salt in

the minimum viscosity mixture of LiF and BeF2 together with a small amount of

235U or plutonium fluoride to initiate the process to be located at least 10 m

underground. The fission products could be stored at the same

underground location. With graphite replacement or new cores and with the liquid

fuel transferred to the new cores periodically, the power plant could operate

for up to 200 yr with no transport of fissile material to the reactor or of

wastes from the reactor during this period. Advantages that include

utilization of an abundant fuel, inaccessibility of that fuel to terrorists or

for diversion to weapons use, together with good economics and safety features

such as an underground location will diminish public concerns.

We call for the construction of a small prototype thorium-burning reactor.

(How this, Dr. Teller's last paper, came into being:

http://ralphmoir.com/media/moirtel.pdf )

MSR - Hatch Reid Introduce New Thorium Nuclear Fuel Bill to Promote Energy

Independence .pdf

"Edward

Teller had a different approach to nuclear safety. He thought that reactors

should be buried deep underground and operate without human intervention.

That way if the reactor broke, you could throw in a few shovels of dirt, and

that would be all it took to keep the reactor safe forever, or so Teller

thought. Towards the end of his life, Teller realized that Alvin

Weinberg's Molten Salt Reactor (MSR) was safe, and that if you built MSRs they

would not have to be buried so deep in order to protect the public. The

MSR was very stable, in fact so stable that no operators were required.

Since the reactor core was a molten fluid, you did not have to worry about

nuclear meltdown. Teller explained it all in his last paper,

Thorium fueled underground power plant based

on molten salt technology."

From:

http://nucleargreen.blogspot.com/2011/06/nuclear-industry-subsidies-part-iii.html

by Charles Barton

________________________________________________________________________________________

THE GOOD:

Molten Salt Reactor advantages

THE GOOD:

Molten Salt Reactor advantages

30-year

automatic power runs with a sealed reactor containment is claimed.

From: MOLTEN-SALT REACTOR CONCEPTS WITH

REDUCED POTENTIAL FOR PROLIFERATION OF SPECIAL NUCLEAR MATERIALS H.F. Bauman,

W.R. Grimes and J.R. Engel (Oak Ridge National Laboratory) H.C. Ott and D.R.

deBoisblanc (EBASCO)

* Note Added in Proof: Since this report was written, a

molten-salt system was identified that may be remarkably resistant to materials

diversion as well as having a conversion ratio near 1.0. This system uses a

denatured fuel mixture of 233U-238U;

processing consists only of removing fission products. These results are only

tentative and require more analysis before the described properties can be

confirmed. - -

" Molten Salt Converter Reactors with No On-Site Fuel Processing

Molten-salt reactors without continuous fuel processing (except

for fission gas removal) have been studied extensively. While not intrinsically

different from MSBRs except for processing, the conversion ratios for such

systems are generally less than 1.0 (typically 0.85 to 0.95) and they have

therefore been called molten-salt converter reactors (MSCRs). In the cases

studied, a fuel charge would remain in the reactor for either 6 or 8

equivalent full-power years (efpy), where the reactor lifetime is taken to

be 24 efpy, or about 30 years of operation at 0.8 plant factor. While the

operating cycle may be long enough to be of interest for a nonproliferation

reactor, the usual MSCR cycle requires continual addition of fissile fuel to

maintain the reactor critical. To meet the criteria of the non-proliferation

reactor, the MSCR would have to be modified to eliminate the need for fissile

feed and to provide another means for controlling the reactivity (keff). To

achieve these objectives, the initial charge could be modified to contain all

the fissile material required for the entire operating cycle. A good way to do

this would be to boost the conversion ratio to near 1.0 by increasing the amount

of thorium in the charge, which would also increase the amount of fissile

material required. This system appears to be quite feasible, and would not be

greatly different from at least one of the MSCR cases studied, in which a

lifetime averaged conversion ratio of 0.98 was obtained based on a fuel salt

containing 14 mole percent thorium.

The problem of controlling reactivity with adding or removing

fissile material also appears tractable. The largest change in reactivity occurs

during the first few months of the cycle, as the rapidly saturating fission

products build in. This change is suited to control by a burnable poison added

to the fuel charge. Reactivity changes would be small during the remainder of

the cycle and could be controlled by conventional shim rods in the core. The

fissile materials usually considered for the startup of molten-salt reactors are

fully enriched uranium, recycled plutonium from light-water reactors, and

recycled 233U from molten salt reactors.

The overall performance of the system is little affected by the

starting material, since (because of the high conversion ratio) after a few

years the main fuel in the system becomes 233U. For this reason, molten-salt

reactors have been examined as burners for the plutonium generated in

light-water reactors. The plutonium could be utilized without requiring the

fabrication of fuel elements, and with minimum requirements for plutonium fuel

transportation.

The performance of the non-proliferation system can be estimated

by comparison with appropriate cases from the MSCR studies. It was assumed that

the average conversion ratio for the non-proliferation system would be roughly

equal to the end-of-cycle conversion ratio for a comparable MSCR system, because

of the effect of the control poison required. For a reactor designed for an

average conversion ratio of 0.95, the estimated fissile specific inventory is

about 3 kg/MWe and the estimated lifetime (24 efpy) fissile requirement is about

1 kg/MWe. It is expected that this system could operate on an 8-efpy cycle,

which would require two fuel-salt changes during the life of the reactor. Thus

the fissile inventory that would be removed with the fission-product-laden salt

charge at the end of a fuel cycle would be approximately equivalent to that

installed with the new salt charge. Even longer cycles, such as 12 efpy

requiring only one salt change per lifetime, appear possible but would have to

be confirmed by further studies.

The diversion resistance of the MSCR-type system would be

approximately equivalent to the previously described systems with processing,

except that the reactor would have to be opened up under supervision one or more

times during its lifetime for replacement of the fuel salt."

Other advantages:

It is hot enough to replace every coal burning

boiler ever made.

It can be made large enough to replace every

coal burning boiler ever made.

It is more docile and predictable during power

changes than all solid fuel reactors since the fission product, xenon-135,

produced by all reactors, immediately bubbles out of the liquid fuel salt and

leaves the core's reaction area without causing the reactor to become "spooky"

as the xenon-135 decays away (it has a nine-hour half-life).

It can be made far more cheaply than today's

solid fuel reactors.

It gets far more energy out of its fuel than

today's reactors.

It can run on the world's nearly endless

supply of dirt-cheap thorium.

It is unpressurized so does not need a

containment vessel, just a nuclear "hot room confinement" shielding and sealing.

Its heat exchangers are virtually unpressurized

(except for perhaps 5 psig inerting) for

minimum cost, maximum safety.

It can be run at a average 80% capacity factor unattended for 30 years

except for an annual "Topping Off" of thorium.

Its negative thermal reactivity makes it an

excellent load follower and confers great safety.

________________________________________________________________________________________

THE BAD: Molten Salt Reactor shortcomings

THE BAD:

Molten Salt Reactor shortcomings

"If it sounds too good to be true, it usually

is." As an old project applications engineer, I've seen a lot of seemingly

good ideas (some of them mine) go sour.

To the author, the WORST THING ABOUT MOLTEN

SALT REACTORS IS HOW HOT THE SALT HAS TO BE BEFORE IT BECOMES MOLTEN:

459°C. or 858°F for the basic fuel salt, Li2BeF4 (Flibe).

This is dauntingly hot. Some metals will

become soft, or even melt, at temperatures like these. Fortunately, the

Nichrome wire used to get the pipes and pumps hot is good for 2,552°F but will

suck up a lot of Amperes

restarting a stone-cold MSR reactor

(52 Amps to get 1,000°F out of AWG 8 Nichrome).

On the other hand, the boiling point of

Li2BeF4 is 1,430°C, or 2,610°F, well above the 1,300°F

cruising temperature of a thorium reactor, provides a huge vapor pressure

safety margin.

The reactor's third cooling loop is a commercial heat

transfer medium, HITEC, for heating and cooling between 300-1100°F (149-538°C)

that is used in process operations, such as reactor temperature maintenance,

high-temperature distillation, reactant preheating, rubber curing, and

rotational molding.

1. To start the reactor, something

strongly fissile, such as uranium-235 at 20% enrichment is needed to initialize

the conversion of non-fissile thorium-232 to fissile uranium-233, far greater

than the 4% enrichment generally used for conventional solid fuel reactors.

20% enrichment is considered the threshold for weapons-grade material.

2.

MSR -

The Bad News from France .pdf As the (non-French speaking,

non-nuclear engineer) author understands this report, they claim you can get

into trouble with certain breeder reactor configurations and they have come up

with an even safer, better, faster, "Molten Salt Fast Breeder Reactor," a

no-graphite core fast neutron reactor optimized for breeding fissile fuels.

The author is talking about the

far more

mundane "Molten Salt Converter Reactor," a graphite-core slow

neutron reactor optimized for 30-year electricity power runs while making almost no

nuclear wastes.

Does anyone know of

criticality issues associated with thermal region converter reactors?

3. I have asked three different

persons who claim to be knowledgeable about Molten Salt Reactors if MSRs were

"ready for prime time." I have been met with silence

from all three.

4. Since salt is corrosive, Molten

Salt reactors and everything associated with them have to be made from the same

more expensive materials we use to make our salt-water nuclear aircraft carriers

and submarines. Materials such as

Hastelloy-N

(an anti-corrosive, radiation-resistant alloy),

brass, and expensive high-temperature plastics.

5.

The buildings in the

following sketches will have to be built for corrosion resistance and

corrosion containment. Notice the pumps in the salt-containing reactor and

steam generator buildings are above the salt

levels. Being at the highest point in a liquid loop makes them more cavitation-prone,

not a good thing.

6.

http://en.wikipedia.org/wiki/Operation_Teapot "MET" was an

atomic bomb with a core of

uranium-233. It was, in fact, detonated in this series of tests. "MET" had a

yield of 22 kilotons - in the same range as the Hiroshima and Nagasaki atomic

bombs. The nuclear weapon equivalent of a steam engine powered airplane.

7. Following from: ESTIMATED COST OF ADDING A

THIRD SALT-CIRCULATING SYSTEM FOR CONTROLLING TRITIUM MIGRATION IN THE lOOO -

MW(e) MSBR

ABSTRACT

"Controlling tritium migration to the steam system of the

1000-MW(e) reference design MSBR power station by interposing a KN03-NaNOa-NaN03

[HITEC] salt-circulating system to chemically trap the tritium would add about $13

million to the total of $206 million now estimated as the cost of the reference

plant if Hastelloy N is used to contain the LiF-BFa salt employed to transport

heat from the fuel salt to the nitrate-nitrite salt, and about $10 million if

Incoloy could be used.

The major expenses associated with

the modification are the costs of the additional heat exchangers ($9 million),

the additional pumps ($5 million), and the 7LiF-BeFa inventory ($4.8 million).

Some of the expense is offset by elimination of some equipment

from the feedwater system ($2 million), through use of less expensive materials

in the steam generators and reheaters (about $2 million), and through an

improved thermal efficiency of the plant (worth about $1 million).

In addition to acting as an effective tritium trap the third

circulating system would make accidental mixing of the fuel and secondary salts

of less consequence and would simplify startup and operation of the MSBR. A

simplified flowsheet for the modified plant, a cell layout showing location of

the new equipment, physical properties of the fluids, design data and cost

estimates for the new and modified equipment are presented." - - (From

ORNL-TM-3428)

_____________________________________________________________________________________

THE UGLY: When running,

thorium's U-232 radiation keeps terrorist's hands out of the cookie

jar.

THE UGLY: When running,

thorium's U-232 radiation keeps terrorist's hands out of the cookie

jar.

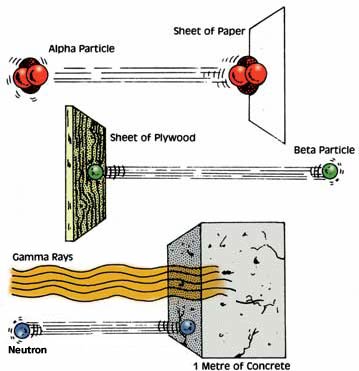

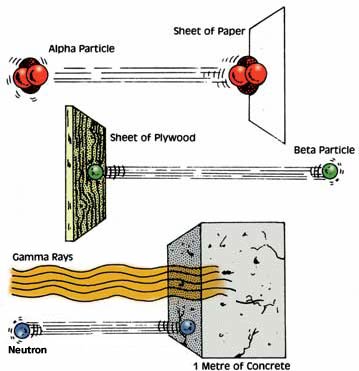

When

running, the molten salt reactor's fission process converts non-radioactive

thorium-232 into radioactive uranium-233. A trace amount of uranium-232 is

also produced. Uranium-232 produces a very strong gamma ray when it

decays. Eventually, only a trace amount - 1% - of any radioactive material

remains as the reactor runs out of fuel, but, while running, you can pick up a 5

rem dose (a significant dose) in a very few minutes if you go around the shielding and get near the

reactor.

Not

necessarily more, but different

radiation containment materials arranged in different order are needed to shield

molten salt reactors. The residual 1% is strongly radioactive at first but

soon decays to 17% in 10 years and eventually to the radioactivity level of

natural uranium ore in a mine after several hundred more years, eliminating the

need for million-year storage of the large amounts of high-level nuclear waste

our uranium nuclear power plants make.

Shoot-from-the-hip comment by someone who really

doesn't like liquid thorium reactors: (

MSR - Steve Bell's Objections to MSRs .pdf )

"The

obstacles to a molten salt liquid thorium reactor are more monstrous, as is

the concept itself. I find it hard (though not impossible) to envision a

nuclear reactor concept that more elegantly combines all the worst imaginable

industrial safety and health problems into one package. While there is too

little space here to elaborate, one difficulty is safely managing tons of

extremely radioactive molten materials at 1100°F being pumped through, into, and

out of the system. Leaks are inevitable and would not be benign events. Even

if you can get past such difficulties, there are enormous infrastructure

investments in new materials and manufacturing. Serious nuclear system

engineers will stay far away from this concept, now and forever." - - Steve

Bell, Friday, August 13, 2010, 12:34:12 PM

MSR - U-232 and the Proliferation-Resistance of U-233 in Spent Fuel - Kang and

von Hippel .pdf

"India's Department of Atomic Energy (DAE) has been concerned about the

occupational hazards associated with the fabrication of fuel containing U-233.

Its long-term ambition is to cleanse U-233 down to “a few ppm” U-232 using laser

isotope purification. In the meantime, a 1993 article from the Bhabba

Atomic Research Center in Bombay reported a 6.7 person-rem summed dose incurred

by workers fabricating a research-reactor core containing 0.6 kg “clean” U-233

containing 3 ppm U-232." (India is committed to thorium as a reactor

fuel.)

"Table 2: Unshielded working hours required to accumulate a

5 rem dose (5 kg sphere of metal at 0.5 m one year after separation).

Metal Dose Rate

(rem/hr)

Hours

Weapon-grade "fresh" plutonium

0.0013

3800. < (This shows how silly we are being

Reactor-grade "stale" plutonium

0.0082

610. about plutonium radiation. - - JH)

U-233 containing 1ppm U-232

0.013

380.

U-233 containing 5ppm U-232

0.059

80.

U-233 containing 100 ppm U-232

1.27

4.

U-233 containing 1 percent U-232 127.

0.04"

(Right) What is needed to stop different

kinds of radiation.

From Wikipedia:

"Thorium fueled reactors may pose

a slightly higher proliferation risk than uranium based reactors

because, while Pu-239 will fairly often fail to undergo fission after

neutron capture and produce Pu-240, the corresponding process in the

thorium cycle is relatively rare. Thorium-232 converts to U-233, which

will almost always undergo fission successfully, meaning that there will

be very little U-234 produced in the reactor's thorium/U-233 breeder

blanket, and the resulting pure U-233 will be comparatively easy to

extract and use for weapons. However, the opposite process

(neutron knock-off) happens as a matter of course, producing

U-232, which has the strong gamma emitter, thallium-208, in its decay

chain. These gamma rays complicate the safe handling of a weapon and the

design of its electronics; this explains

why U-233 has never been pursued for weapons beyond proof-of-concept

demonstrations."

The

above is a strong argument for a sealed 30-year reactor on a barge (below).

If something goes bad, the reactor barge goes back to the factory where

specialized equipment with proper shielding can be used to efficiently effect repairs. If

something doesn't go bad, after 30 years the reactor goes back to the factory

for either disposal or refurbishing, refueling, and reuse. - - Jim Holm

Over half of the 1,200 supersized power plants are on navigable

water, making shipyard mass produced concrete "Reactor Barges" a

cost-attractive approach. They would be parked on pilings in filled-in slips cut next to a

power plant’s turbine gallery. If desired, a great deal of physical security can

be economically added. Such "Reactor Barges" would act as catch basins in the

event of an accidental fuel salt spill, "float" on the ground during an earthquake, be

"high and dry" in the more likely event of a storm surge, be easily returned to

a factory for its 30-year refurbishing-refueling, and be easily removed forever

when no longer needed, leaving no residual radiation or nuclear power site

decommissioning costs.

_______________________________________________________________________

THE ROUGH SPOTS:

THE ROUGH SPOTS:

Out gassing of radioactive Xenon-135 and cesium something or

other. Nothing solid uranium reactors don't also do but gasses stay

trapped in the zirconium tubes that hold the fuel pellets. Xenon-135 makes

reactors "squirrely" and was a big reason the operators screwed up at Chernobyl.

Since the xenon-135 bubbles out of the water-like liquid salt immediately and

thus does not affect the reactor's fission strength, this is one more reason

molten salt reactors are well-behaved. A simple and inexpensive out-gas

handler was developed for the Molten Salt Experimental Reactor.

________________________________________________________________________________________

General Considerations

General Considerations

1. Simple elegance rather than mechanical precision.

"Unpressurized" is the word that makes this reactor and its

associated equipment far cheaper than equivalent solid fuel rod reactors.

A major disadvantage of MSRs is that the molten salt is

corrosive. The reactor system thus has to be made out of corrosion-resistant

materials such as

Hastelloy-N.

2.

Comment by Bruce Hoglund:

"There are no technical obstacles for the deployment of a

'sealed' MSR that operates with no chemical processing. Such a reactor

could operate for ~30 years with no processing other than allowing the noble

gases to naturally bubble out of the salt and periodic additions of fissile

material.

Since it would be advantageous due to environmental, economic,

and resource conservation concerns to achieve as much reclamation of the

expensive salt after (or during) the 30 year operation period, a parallel

development of various salt processing methods should occur

(78)

(much of which has already been done as part

of the Integral Fuel Reactor [IFR] project's fuel cycle studies). If this

strategy of attempting to remove very long term fission product buildups in the

salt is pursued, the salt can continue service in another reactor after the

first MSR has reached the end of its life.

This would not only greatly reduce decommissioning costs and

difficulties (as the vast majority of the radioactivities go with the salt and

removed fission products), but allow the expense of the salt to be amortized

over >100 year periods!"

78. Page 94, "Conceptual Design Characteristics of a Denatured Molten-Salt

Reactor With Once-Through Fueling", J.R. Engel, W.R. Grimes, H.F. Bauman, H.E.

McCoy, J.F. Dearing, & W.A. Rhoades, (1980), ORNL/TM-7207, 156 pages.

http://www.moltensalt.org/references/static/home.earthlink.net/bhoglund/multiMissionMSR.html

3. There is a fairly recent study on the estimated cost of electricity

from 1, Molten-Salt reactor powered plant, 2, conventional nuclear, and 3, coal.

MSR - Cost of electricity from Molten Salt Reactors - coe_10_2_2001.pdf

There have been no studies on what it would cost to produce electricity from a

plant converted from coal to MSR nuclear.

________________________________________________________________________________________

Uncertainties, unanswered questions

Relocated to:

Questions. Things I know

I don't know.

________________________________________________________________________________________

References

References

http://energyfromthorium.com/

Kirk Sorensen, is the

Molten Salt Reactor / LFTR's current

U.S. custodian. If you check out only one site . . .

MSR-FUJI - General

Information .pdf -

A quick presentation.

MSR Development in Japan .pdf

MSR -

What is Molten Salt & Its Technology_ .pdf

MSR - HITEC Heat Transfer

Salt .pdf

MSR Thorium Mining in Turkey - amr-thorium-project-2011.pdf

There is a book available from Amazon on how the

heat exchangers were designed to be fabricated (by R.G. Donnelly, $9.99). The

inexpensive "shell and tube" heat exchangers to make the steams necessary to replace the coal boiler could

come from Babcock & Wilcox or perhaps 50 other boilermakers worldwide.

Heat Exchangers - Classification of Heat Exchangers - 0471321710 .pdf

Why did our nuclear industry pass on

this one? While the MSR is not perfect, consider all the shortcomings of

what we have now.

This is the "Model T" of nuclear reactors. Intended to

replace coal right from the start and safe versions are easy to build in any size. It is the low-cost

nuclear replacement for all large coal fires.

The mitigation money to pay for them for them is there. The

proof-of-performance prototypes have been run. The design studies for 350

and 1,000 megaWatt (electrical) operational units have been worked out.

All we need now are site, construction, and shop detail drawings and the courage to actually

do it.

http://home.earthlink.net/~bhoglund/mSR_Adventure.html

________________________________________________________________________________________

Molten Salt

Reactor Basics

The yellow fuel-carrying salt is

shown flowing into and out of the reactor in tubes drilled in an otherwise solid

block of graphite (colored black) - about 90% of the volume of the reactor

vessel is occupied by graphite.

Molten Salt

Reactor Basics

It cannot melt down because being melted

is its normal state. Being an unpressurized pool of molten salt, it

can't explode. If, for any reason, the salt gets too hot, a freeze plug in

the bottom of the reactor melts and the liquid "fuel salt" drains into

the blue emergency

dump tanks beneath the reactor. There, away from the reactor's moderator

rods, the fuel salt immediately ceases to fission and is passively cooled by a

sodium-potassium cooling system.

The neat thing about using molten salt is that if

any leaks out, it immediately cools, turns solid, and doesn't go anywhere -

think red-hot lava flowing from a volcano.

The second stage "Coolant Salt" is non-radioactive, clean, pure melted

salt - also as fluid as water - with no radioactivity. This is the salt

that carries the heat from the reactor to the "shell and

tube" heat

exchanger (lower right, above) to make the steam needed to drive the turbine which, in turn, drives

the electricity generator.

The "Chemical Processing" module is a small "hot" room

located next to the reactor. It functions like a swimming pool cleaner - spent

nuclear fuel is removed, fresh fuel is added.

The reactor has an

extremely high negative temperature coefficient and tends to "load

follow" (think cruise control) extremely well so thorium reactor experts

say only a few control rods will do. (Image from Idaho National Laboratories Gen-IV Reactor

Project.)

________________________________________________________________________________________

More about Molten

Salt Reactors

More about Molten

Salt Reactors

http://energyfromthorium.com/

Kirk Sorensen - More than anyone is the LFTR's current

custodian.

http://www.energyfromthorium.com/pdf/ Kirk Sorensen has provided us

with a gold mine of information.

http://www.asme.org/kb/news---articles/articles/nuclear/molten-salt-reactors

http://en.wikipedia.org/wiki/Molten-Salt_Reactor_Experiment

http://en.wikipedia.org/wiki/Molten_salt_reactor

MSR - Safety and Licensing Aspects of the Molten Salt Reactor - 120507.pdf

Molten-Salt-Reactor

Technology Gaps .pdf

MSR - High Temperature Molten Salt Coolants - Literature-IAEA .pdf

MSR - Thermal and Fast Spectrum Molten Salt Reactors -

msr_deliverable_doe-global_07_paper.pdf

http://home.earthlink.net/~bhoglund/ Bruce Hoglund Home page

http://www.moltensalt.org/ Bruce

Hoglund

http://www.moltensalt.org/references/static/home.earthlink.net/bhoglund/multiMissionMSR.html

Thorium Molten Salt Reactor covered in Wall Street Journal

The 1965 and

1972 engineering projects for producing a 1,000 megaWatt (electrical) liquid

reactor.

Molten salt reactors -

As per World Nuclear Association

During the 1960s, the USA developed the molten salt breeder reactor concept

as the primary back-up option for the fast breeder reactor (cooled by liquid

metal) and a small prototype 8 MWt Molten Salt Reactor Experiment (MSRE)

operated at Oak Ridge over four years. U-235 fluoride was in molten sodium and

zirconium fluorides at 860°C which flowed through a graphite moderator. There is

now renewed interest in the concept in Japan, Russia, France and the USA, and

one of the six Generation IV designs selected for further development is the

molten salt reactor (MSR).

In the MSR, the fuel is a molten mixture of lithium and beryllium fluoride

salts with dissolved enriched uranium, thorium or U-233 fluorides. The core

consists of unclad graphite moderator arranged to allow the flow of salt at some

700°C and at low pressure. Heat is transferred to a secondary salt circuit and

thence to steamo.

It is not a fast neutron reactor, but with some moderation by the graphite is

epithermal (intermediate neutron speed). The fission products dissolve in the

salt and are removed continuously in an on-line reprocessing loop and replaced

with Th-232 or U-238. Actinides remain in the reactor until they fission or are

converted to higher actinides which do so. MSRs have a negative temperature

coefficient of reactivity, so will shut down as temperature increases beyond

design limits.

Liquid Fluoride Thorium Reactor

The Liquid Fluoride Thorium Reactor (LFTR) is one kind of MSR which breeds

its U-233 fuel from a fertile blanket of liquid thorium salts. Some of the

neutrons released during fission of the U-233 salt in the reactor core are

absorbed by the thorium in the blanket salt. U-233 is thus produced in the

blanket and this is then transferred to the fuel salt. LFTRs can rapidly change

their power output, and hence be used for load following. Because they are

expected to be inexpensive to build and operate, 100 MWe LFTRs could be used as

peak and back-up reserve power units.

Fuji MSR

The Fuji MSR is a 100 MWe design to operate as a near-breeder and being

developed internationally by a Japanese, Russian and US consortium. The

attractive features of this MSR fuel cycle include: the high-level waste

comprising fission products only, hence shorter-lived radioactivity; small

inventory of weapons-fissile material (Pu-242 being the dominant Pu isotope);

low fuel use (the French self-breeding variant claims 50kg of thorium and 50kg

U-238 per billion kWh); and safety due to passive cooling up to any size.

________________________________________________________________________________________

Advanced LIQUID FLUORIDE

THORIUM (LFTR) Nuclear Reactors

Advanced LIQUID FLUORIDE

THORIUM (LFTR) Nuclear Reactors

The following advanced MSR

versions are not suitable/intended for the author's idea for repowering an existing

superheated or supercritical coal, natural gas, or oil burning steam

driven electricity generating station.

(Right)

A proposed 200 mWe Thorium powered power plant. For

more, visit:

http://itheo.org/articles/itheo-presents-ithems

These folks have gone beyond steam turbines to

gas turbines in their designs. There are some good reasons for this.

A big reason is that molten salt reactors and water don't get along too well and

need an additional buffer cooling loop which raises costs and lowers both

efficiency and reliability. See Gen-IV gas turbine diagram below.

The author notes that gas turbines are not all roses either. Note that it

has a power-sucking 2-stage gas compressor. Does this really make it that much better than

conventional superheated steam without smokestack losses? It does avoid

that third stage of heat exchanging - sort of - but you still have that

recuperator and intercooler.

Take a close look at the MSR-Gas Turbine

below. One might consider the gas turbine's

precooler and intercooler pair and the

steam plant's steam condenser a wash. - Grumpy old retiree.

Advanced LIQUID FLUORIDE

THORIUM (LFTR) Nuclear Reactors

http://energyfromthorium.com/

Kirk Sorensen - More than anyone is the LFTR's current

custodian.

http://www.energyfromthorium.com/pdf/ Gold mine of information.

http://msr21.fc2web.com/English.htm International Thorium Molten Salt

Forum (Japanese)

http://www.energyfromthorium.com/FluidFuelReactors.html Excellent

Primer on Aqueous Reactors (1958)

http://thorium.mine.nu/UCTEA/Technical_Readings.html Technical Papers

and Readings

http://en.wikipedia.org/wiki/Fuji_Molten_Salt_Reactor

http://www.ithems.jp/e_purpose.htm

http://itheo.org/articles/itheo-presents-ithems

Links

http://nucleargreen.blogspot.com/2010/07/fuji-project-seeks-300-million-in.html

http://home.earthlink.net/~bhoglund/

http://www.ltbridge.com/company

http://www.world-nuclear.org/info/inf62.html

http://thoriummsr.com/

Thorium a Viable Option .pdf

Thorium Based Fuel Options for the Generation of Electricity -

31030535.pdf

Thorium fuel cycle - Potential benefits and challenges - TE_1450_web.pdf

Thorium fuel utilization - Options and trends - te_1319_web.pdf

Thorium Proponent Kirk

Sorenson .pdf

________________________________________________________________________________________

Here is the modern PhD's dream for thorium-fueled

molten salt reactors.

A power plant that does not boil water - something man has had to do for 300

years to get mechanical energy from heat.

This power plant heats a gas such as helium and, on paper, should be 5% to 10%

more efficient than molten salt boiler steam power plant.

Hitting the Sound Barrier: Turbines are speed-of-sound sensitive devices and the

speed of sound in helium is about twice as fast as the speed of sound in steam.

Remember inhaling some helium from a helium balloon and then talking like a

chipmunk? These turbines are going to be difficult to build and maintain.

________________________________________________________________________________________

Websites by thorium

enthusiasts

http://nucleargreen.blogspot.com/

Charles Barton - It

is his father's reactor.

http://energyfromthorium.com/

Kirk Sorensen - More than anyone, the LFTR's current

custodian.

http://www.thoriumenergyalliance.com/

http://www.thoriumenergy.com/

http://www.thorium1.com/

http://www.ltbridge.com/

http://thoriumsingapore.com/content/

http://msr21.fc2web.com/English.htm

http://torium.se/ Thorium Electro Nuclear

Ltd.

http://www.kiae.ru/e/engl.html

http://www.thorenergy.no/ Norway

________________________________________________________________________________________

Small Particle Accelerator Could Power

Thorium Reactors.

Popular Science (6/16, Boyle) reports on the Electron Model of Many

Applications, or EMMA, "a small particle accelerator that could be used to power

future thorium reactors." The article notes that thorium is drawing increased

interest as the basis for reactors because of its safety in comparison to

traditional nuclear reactors. Getting thorium to release energy "is one obstacle

to building small thorium reactors," an issue EMMA could resolve. Popular

Science notes, "EMMA is the first non- scaling, fixed-field,

alternating-gradient (NS-FFAG) accelerator, qualities that make it easier to

operate and maintain, more reliable and compact, more flexible and more

efficient, according to British researchers."

Market Qualms Make Safer Reactor

Designs Slow In Coming, Experts Say.

In an "Ingenuity Of The Commons" blog entry for Forbes (4/22), Jeff McMahon

wrote, "Safer nuclear reactors have been available for years, but the energy

market prefers less expensive conventional designs, a nuclear energy expert from

Argonne National Laboratory said Thursday." Argonne Nuclear Energy Division

director Hussein Khalil said that there is a "tremendous incentive" to develop

"new reactors that have more inherent, intrinsic safety features, and we've been

doing this for some time at ANR" and while they have "been developed to a fairly

high degree of technical maturity, but none of them have been successfully

commercialized yet because it appears they can't yet compete on an economic

basis with the existing technology." Khalil said, "liquid-metal and sodium

cooled reactors are examples of safer reactor designs," but noted they haven't

been selected because it's easier and cheaper to repeat older designs than risk

the "'regulatory uncertainty' faced by power companies that risk new designs."

________________________________________________________________________________________

JUMP:

Directory

Top

Previous

Next